By Renee Wood

Air conditioning is used daily by millions of people across the world, with 40 per cent of a building’s energy consumption going towards heating ventilation and air conditioning.

The systems are in houses, high-rises, health services, fridges, cars and more – controlling temperatures to allow life to continue when it’s scorching hot or freezing cold outside.

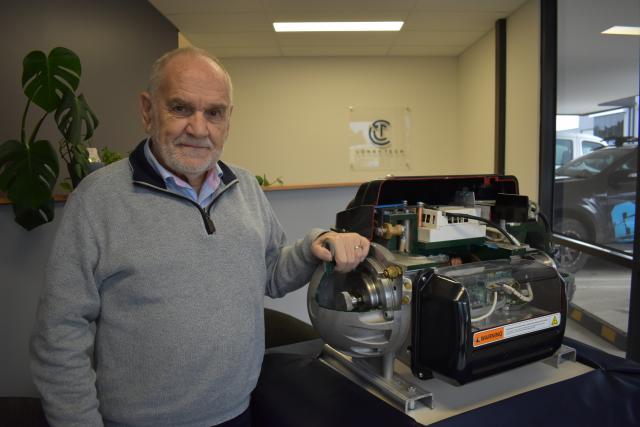

It’s a luxury that you might not give much thought to, however, Yarra Glen resident Ron Conry certainly has, dedicating much of his life to improving the system we’ve all come to lean on.

Mr Conry has now been honoured for his significant service to the heating, ventilation, air-conditioning and refrigeration industry, being appointed a Member of the Order of Australia.

Mr Conry said he was surprised to receive the accolade.

“We’ve received awards from the EPA in the USA and from Natural Reserves Canada and Institute of Refrigeration in London and all over, but getting one home grown, it’s special,” Mr Conry said.

The AM recipient has been in the industry for 56 years, starting out with an apprenticeship as a refrigeration mechanic.

Mr Conry said he’s never worked on a refrigerator and he ‘wasn’t a clairvoyant’ to picture the future of air conditioning and cooling being such a staple of modern day life.

“My idea of refrigeration mechanic was a mechanic that fixes refrigerators, it wasn’t until I got into it that I realised what it was all about and I do like high speed machinery so part of what I did was working on high speed machinery,” he said.

It’s also something he thinks is undervalued and overlooked.

“People see the air conditioners registered as the thing on the wall with thermostat – they don’t understand behind it is huge capital costs in the building.”

His career spans decades, but it hasn’t just been a career – Mr Conry’s played a revolutionary role in evolving the systems.

Mr Conry has been part of several companies within Australia and overseas and has several patents for parts and improvements to air-conditioning and refrigeration systems.

He invented the modular chiller and the Turbocor Compresser – something he says has been biggest invention and achievement to date.

The Turbocor Compressor has been installed in high-rise buildings more than 100,000 times across the world and has saved a billion tons of Co2.

Mr Conry created this by getting rid of friction and the dependency on oil by inventing magnetic bearings to take it out of the equation.

This formed a compressor that was faster and more efficient in delivery of the air-conditioning, reducing energy consumption and cutting emissions.

It helped to see California out of rolling brown outs in the early 2000s following the power companies providing blanket rebates to anyone putting this compressor in a building.

“You would struggle to walk into a building in any capital city in Australia that’s not cooled by Turbocor,” he said.

During its development, Mr Conry was told it was ‘impossible’.

“I was told by many experts when we’re in development, the compressor what I was doing was impossible, you can’t do it. By their way of looking at it, it was impossible but we found a solution,” he said.

“Until I’m comfortable in my gut I don’t believe it.”

Now Mr Conry said he’s comfortable about his next ambitious invention with Conry Tech, creating a system that will be ‘re-inventing air-conditioning and heating’.

Over the several patents created, the Chief Technology Officer will be taking all that knowledge and applying it to a new approach.

“I am very comfortable but I still get people that will say it can’t be done and we’re still saying – prove it,” he said.

“This new one is totally different – the last one we just invented the compressor and before that I invented modular chiller, so they’re just parts, now we’re redeveloping the complete system.”

Sam Ringwaldt, CEO of Conry Tech, nominated Ron for the prestigious honour, working with Mr Conry for decades both indirectly and directly.

Mr Ringwaldt said he admires the way that he can highlight an issue and work tirelessly to find a solution.

“He has the ability to essentially take a blank piece of paper and say, what are the problems and right now let’s just fix them,” Mr Ringwaldt said.

“Rather than just saying how do we improve this a little bit, it’s ‘we might need to make something entirely new to fix these problems’ – maybe we can’t do it the way it’s always been done.”

Mr Conry and Mr Ringwaldt, now both working together, said the industry is eager to see what Conry Tech is working on.

“I’m fairly credible in the industry so it’s not easy to get people’s interest in what we’re doing,” Mr Conry said.

“There’s a little bit of anticipation in the market of what is Ron working on now,” Mr Ringwaldt said.

Mr Conry has lived overseas for 20 years following the development of the Turbocor Compresser which first started here in Australia in 1994.

To raise capital for the invention, which cost 146 million to make, he moved the whole operation to Canada in 2000 following the country’s government providing millions in funding.

Now back in Australia since 2020, Conry Tech has formed in the hopes the next revolutionary machine will be produced on home soil.

Mr Conry has spent the past four years building prototypes and it’s something that will dramatically use less energy, with energy conservation the most sustainable outcome.

“I think the only way they can become carbon neutral and ever hit this 2050 goal is by doing something radically,” he said.

“You can put all the solar they like but the sun doesn’t shine very much at eight o’clock at night and batteries are just as pollutant as what they’re trying to replace. They’re expensive and to dispose of it is a major problem.

“Batteries are a help, but they’re not the solution and the best solution would be for nobody to use electricity at all.”

The next machine aims to reduce power consumption by 70 per cent and is also tackling heating to transition away from gas.

“There’s this push for electrification of heating, but the solutions on the market today are really that work inadequate and so we believe we can do something that’s three times better than the best solution on the on the market for heating now,” Mr Ringwaldt said.

The creation of high tech jobs and building a factory that is fully automated by robots will be needed to manufacture the new invention on mass.

Both Mr Conry and Mr Ringwaldt agreed it’s hard to manufacture something like this locally with the associated industries dissipating offshore – but they’re willing to try to see the benefits come back to the country.

Mr Ringwaldt said by having production in Australia it would generate billions for the economy. Following Turbocor for example that is believed to have given Canada $10 billion to its ecosystem and it cost the government 26 million dollars.

“There’s a very heavy focus on renewables obviously in the industry, but it takes a long time to build up your power grid to transition to renewables, but for faster and better long term is just not use the power,” he said.

The latest development for the invention was partnering with University of New South Wales for a research grant of $3 million.

The prototypes will be installed on campus buildings in the next 9 to 12 months – this potentially being the start of what’s to come for the heating and cooling industry.

“People say it can only be done a certain way just because you can’t do it or no one else has done – [but that] doesn’t mean it can’t be done. I mean, if it couldn’t be done people wouldn’t be flying,” Mr Conry said.